Say goodbye to wasted food and hello to extended freshness with our innovative fresh-keeping technology!

-

Mon - Sat : 09:00 - 22:00(GMT+8)

-

sales@chesenbio.com

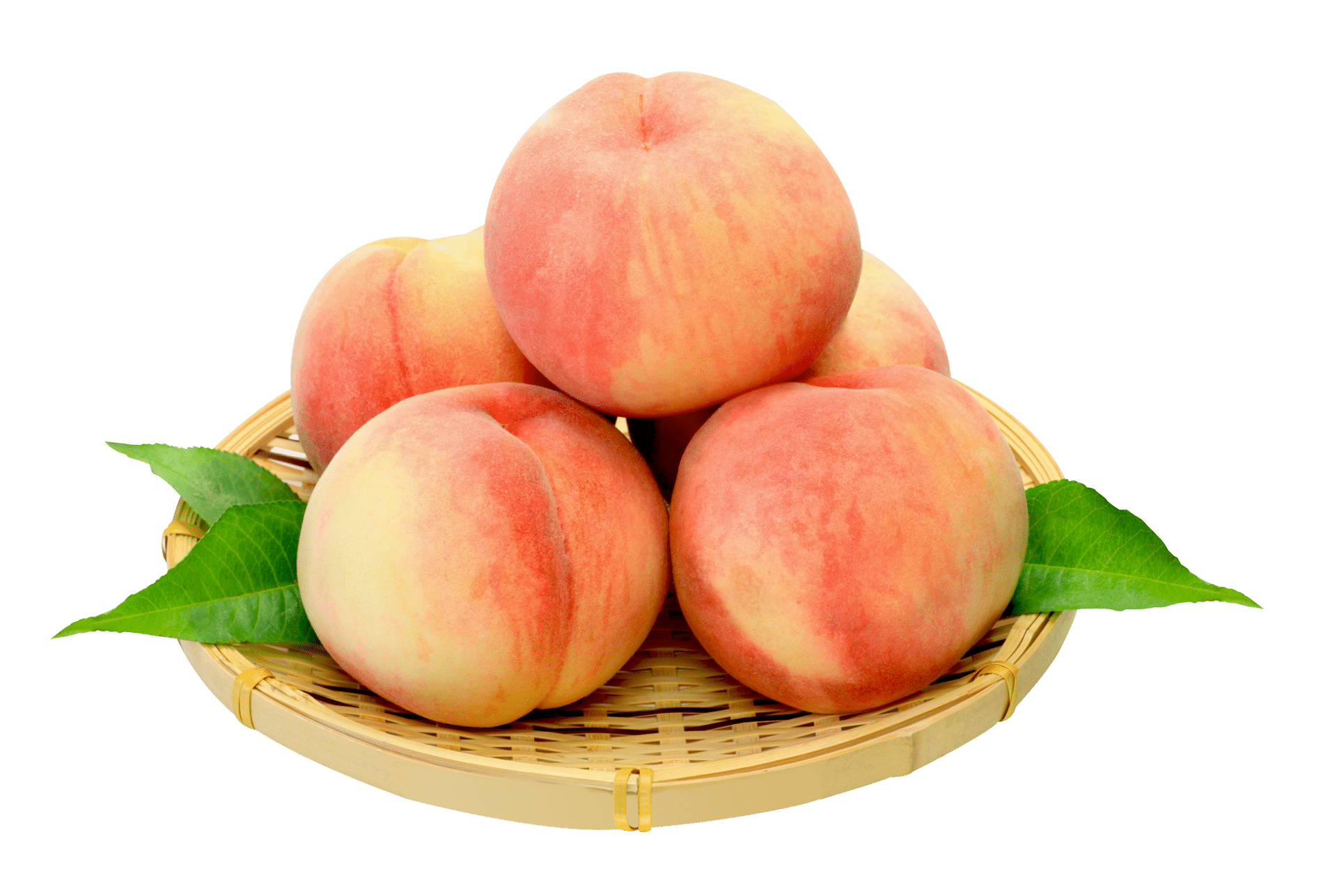

1-MCP for peach storage

Storage and Preservation Technology of Peach by 1-MCP

Low-temperature storage is currently a good method of fruit storage, but peaches are very sensitive to temperature. So storage at low temperatures is prone to chilling injury. As a climacteric fruit, peach is characterized by a peak in ethylene production in concert with a burst of respiration during the ripening stage. Commercial ethylene inhibitor, 1-MCP, is widely used to improve storage potential and maintain fruit quality in peach fruit. The application of 1-MCP can delay peach softening, inhibit respiratory rate decrease, maintain titratable acid concentration and alleviate chilling injury.

1. Variety and storage characteristics of peach

The storability of different peach varieties varies greatly. Generally, early-maturing varieties are not resistant to storage and transportation. The mid-late ripe varieties have good storage resistance. The nucleus-resistant varieties and soft solute varieties have poor storage resistance.

Peach is a climacteric fruit. Appropriate low temperature, low oxygen and high carbon dioxide can reduce the amount and effect of ethylene. The result is an extension of the peach storage time. However, peach is sensitive to low temperature and is prone to low temperature damage. It will cause freezing damage below -1 °C, generally storage temperature is 0 ° C ~ 1 ° C. Fruits are more likely to lose water during storage, requiring a higher humidity in the storage environment, with a relative humidity of 90%-95%.

2. Harvesting and precautions of peach

2.1 Harvesting of peach

The harvest maturity of the fruit is the main factor affecting the storage effect. Premature harvesting will affect the flavor of the fruit, and it is susceptible to cold damage; the harvest is too late, the fruit hardness is reduced. So it is vulnerable to mechanical damage and causes a lot of decay. Therefore, it is required that the fruit should not only grow and develop fully, can basically reflect the color and flavor characteristics of the variety, but also can maintain the flesh quality of the fruit. At this time, it is suitable for picking. That is, when the fruit reaches the ripening of seven or eight. It is important to note that the fruit should be brought with a fruit stalk during harvesting. Otherwise the detachment of the stalk may cause corruption.

2.2 Precautions of peach

After the fruit is fully developed, the peel begins to chlorotic, the flesh is slightly hard, and the colored variety is basically full color when it is hard ripe. When the bottom color of the fruit is green or light green, the fruit fluff begins to decrease, and the flesh is slightly hard, the colored face is colored, it is ripe for seven or eight. Peaches of these two growth periods are more resistant to storage and long-distance transportation.

Due to the inconsistent maturity of peaches, the general varieties need to be harvested 2 or 3 times. When harvesting, it is strictly prevented from crushing and stabbing, and the fruit is taken with a fruit handle. It is better to harvest at low temperature in the morning. Pick up residual, wound, inferior, deformed, and dirt fruits with the processing. During picking and handling, remember to take it lightly and gently to prevent crushing. The packaging container of peach is generally suitable for 5 kg – 10 kg.

3. 1-MCP treatment of peach

3.1. Pre-cooling

Peach that is quickly pre-cooled after harvesting and transported by cold chain can prolong storage life. Pre-cooling of peaches is air-cooled and 0.5°C-1.0°C water-cooled. The air-cooling method is commonly used in production.

3.2. 1-MCP treatment

After pre-cooling, use 1-MCP for fresh-keeping treatment, inhibit the release of ethylene, reduce the respiratory intensity, maintain the hardness and color of the fruit, and reduce the consumption of nutrients. This can greatly improve the storage and shelf life. The following are several application methods of 1-MCP on peaches.

3.2.1 1-MCP treatment method applied on peach

Application of 1-MCP was at both 20 and 0 °C for 5, 10 and 20 h and at concentrations from 0.5 to 20 μl/l. When treated at 0 °C the fruits were stored for 5 days before removal to 20 °C for ripening. 1-MCP slowed fruit softening in a concentration and time dependent manner, extending the period before the fruits became over-soft. The inhibition of softening was greater when fruits were treated and held at 20 °C than if they were treated at 0 °C and held for 5 days at 0 °C before ripening at 20 °C. 5 μl/l of 1-MCP for 20 h was the optimum concentration and time of treatment for inhibition of softening.(Giorgia Liguori, 2004)

3.2.2 1-MCP&Hot water treatment method applied on peach

Combined heat and 1-MCP (HM) treatment is a new postharvest technology. HM treatment can maintain peach fruit quality during room temperature (RT) storage. HM treatment is more beneficial for peach fruit stored at RT than at low temperature(Chen Huan, Xiujuan An, 2018) .

- Peaches are treated with hot water at 48℃ for 10 min and then with 10 μl/l 1-MCP for 12h.

- After treatment with 1-MCP, Peaches are stored at 4-25℃ with 85-90% humidity.

3.2.3 1-MCP&Ethanol treatment method applied on peach

Peach with suitable maturity is post-harvested with ethanol and 1-MCP fumigation. Then refrigerated(Not less than -1 ° C), transported or sold. The treatment dose of ethanol is 50-900 μl / L. The μl / L is the volume of liquid ethanol / the volume of the fumigation container. The 1-MCP treatment dose is 0.5-4 ppm. The treatment time is the end of fumigation within 5 days after the harvest. The length of treatment is 12-24 hours. The treatment temperature is room temperature (20 ° C). After the treatment is finished, the ethanol gas in the fumigation environment is discharged. Appropriate maturity refers to the color, flavor and taste of the peaches of the variety, and the hardness meets the requirements of transportation time or storage period.

The fumigation treatment must be carried out under sealed conditions. The treatment method is simultaneous fumigation of ethanol and 1-MCP, or fumigation with ethanol and then fumigation with 1-MCP, or fumigation with 1-MCP followed by fumigation with ethanol.(Patent application number: 200910002899.x, Patent authorization notice number: CN 101473869 B)

4. Storage technology

4.1 Storage conditions

Peach is sensitive to low temperature and is prone to low temperature damage. It will cause freezing damage below -1 °C. Generally, the storage temperature is 0 °C-1 °C. Fruits are more likely to lose water during storage, requiring a higher humidity in the storage environment, with a relative humidity of 90%-95%. The temperature of medium and early maturing varieties is slightly higher. Since peach fruit is sensitive to low temperature, storage at 0 °C for a long time is likely to cause chilling damage. In order to prevent or reduce the occurrence of chilling damage, facilities with high temperature control accuracy are required.

The suitable oxygen concentration for storage of peaches is 1% to 3%, and the concentration of carbon dioxide is 4% to 5%. When stored in a physiological package, the carbon dioxide concentration is below 8% and the oxygen concentration is between 5% and 14%. It should be checked regularly after storage, once a day for short-term storage and once every 3 to 5 days in the medium and long term.

4.2 Storage method

Cold storage: Peach can be stored for 15 days to 30 days at 0 ° C and 90% relative humidity, and can be extended to 60-75 days after treatment with 1-MCP. Intermittent temperature rise during cold storage can avoid or reduce chilling damage and prolong storage life. The method is: the peach which is refrigerated at a low temperature of -0.5 ° C – 0 ° C is heated to room temperature (18 ° C – 20 ° C) for about 1 day – 3 days every 2 weeks, after which the low temperature storage is resumed.

Controlled atmosphere storage: It is recommended to store nectarine at 0 °C, 1% oxygen plus 5% carbon dioxide, the storage period can reach 45 days, which is 1 time longer than ordinary refrigeration. In the absence of conditions to achieve standard air conditioning (CA), peach fresh bags and gas fresheners can be used for simple atmosphere storage (MA). The specific method is as follows: after the peach is harvested and pre-cooled, it is put into the refrigerated special fresh-keeping bag, and the controlled atmosphere preservative is added to tighten the bag mouth. The gas composition in the bag is maintained at the oxygen concentration of 0.8%-2%, and the carbon dioxide concentration is 3%-8%. Next, Okubo, Yanhong, and Mid-Autumn Festival can be stored for 40 days, 55 days – 60 days, 60 days – 70 days, respectively, and the fruit can still maintain normal post-ripening ability and commodity quality.

4.3 Storage management

Sterilization: It should be sterilized regularly during storage, preferably every half month, and the effect of bactericide rotation is better.

Ventilation: every 15 days or so to change the gas, the ventilation time is controlled in about half an hour, choose the sunny day when the outside temperature is low.

5.Contact us

For more detailed information about 1-MCP on peach, please contact us.