Say goodbye to wasted food and hello to extended freshness with our innovative fresh-keeping technology!

-

Mon - Sat : 09:00 - 22:00(GMT+8)

-

sales@chesenbio.com

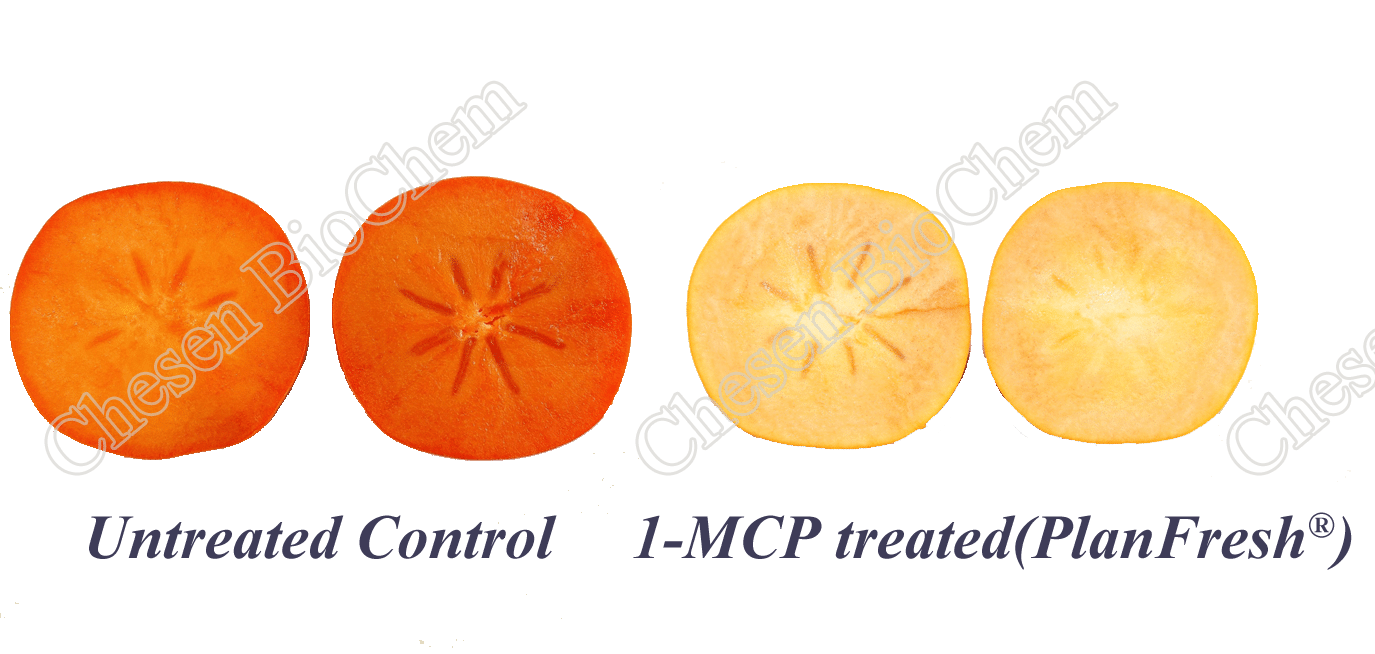

1-MCP Application on persimmon

1.Persimmon varieties and storage characteristics

Persimmon is a typical respiratory climacteric fruit because they produce a small but significant amount of ethylene during ripening. 1-MCP(1-Methylcyclopropene) reduces ethylene effects in a range of fruits including persimmon. The molecular structure of the gases 1-MCP (C4H6) and ethylene (C2H4) are very similar. 1-MCP binds to the receptor site for ethylene, thereby blocking its action.The application of 1-MCP delays the ethylene climacteric and reduces the rate of fruit softening even for fruit stored at 20°C. The response may be as dramatic as a doubling of storage life.

Commercially and in general, there are two types of persimmon fruit: astringent and non-astringent. The astringent variety ‘Hachiya’ and the non-astringent variety ‘Fuyu’ are widely planted. The heart-shaped Hachiya has a high tannin content, which makes the unripe fruit astringent and bitter. The tannin levels are reduced as the Hachiya matures. Persimmons like ‘Hachiya’ must be completely ripened before consumption. When ripe, this fruit comprises thick, pulpy jelly encased in a waxy thin-skinned shell. Fuyu looks like tomatoes, are edible in the crisp, firm state but it has its best flavor when allowed to rest and soften slightly after harvest.

Skin colour generally seems to be a good external parameter for use in predicting the storability and shelf life potential, loss of firmness during storage is lower in fruit picked less ripe compared to fruit picked more ripe.However,there is a compromise between storing ‘greener fruit’ which stores longer and external quality of more highly coloured fruit. Most studies show that within an orchard either very early-season (physiologically immature) or very late-season fruit (physiologically over-mature) store more poorly.

2.Note of picking

You can begin picking astringent types of persimmon in the early fall when the days are still a bit warm, and the fruit is hard but fully colored. Non-astringent types of persimmon are ready to harvest when they a have a deep flushed apricot hue with pink overtones.

Growers should harvest only mature fruit based on maturity standards. Persimmons are harvested with the calyx attached. Growers should clip persimmons from the tree using special-purpose precision secateurs to ensure a good appearance and the quality of the calyx.The precision secateurs have been designed to make a clean cut above the calyx, leaving the calyx attached to the fruit, without bruising the fruit or damaging the branch. Then growers should trim the stem to avoid puncturing other fruit. Don’t stack them in a basket after picking, as they easily bruise. Growers should place persimmons by hand into harvest crates either 2 or 3 layers deep. You could use bubble wrap between layers of fruit to reduce damage.

3.Prepare before storage

3.1 Pre-conditioning

The drastic softening of fruit after cold storage is the result of chilling injury caused by low temperatures. This problem can be partially attenuated through pre-conditioning fruit prior to longer term storage. Preconditioning reduces the loss of firmness during and after the removal from storage. Suggested temperature and duration for pre-conditioning is 2 days at 23°C. There may be some advantages in pre-conditioning persimmon fruit prior to treatment with 1-MCP, particularly to remove damaged or diseased fruit.

3.2 Chamber management

Eliminate the odor and debris inside the store. Use Potassium permanganate or Sulfur to disinfect the cold room. Cool down temperature of the cold room to 15°C two days in advance, put the cooled persimmons in the cold room, keep gaps between persimmon stacks for ventilation. Adjust the temperature of chamber when finish storing all of the persimmons. Try to fill the chamber with fruits in 7 days, then treat them with 1-MCP in time.

4.1-MCP treatment on persimmon

1-MCP research has been conducted in all the major persimmon growing regions around the world. Most researchers aim at reducing rapid fruit softening of the major astringent varieties after removal of astringency, although there has been considerable research with fruit.1-MCP effectiveness in improving fruit storability is dependent on the time of application. A longer delay before 1-MCP treatment is associated with increasing ethylene concentration in the fruit which in turn limits fruit storability. 1-MCP will not prevent damaged fruit from ripening pre-maturely. Growers should remove these fruit after pre-conditioning and before cool storage.

It is necessary to ensure fruit to be treated is of high quality and at the correct maturity before application of 1-MCP. Take all necessary care during picking and packing (into bulk bins/trays) to ensure fruit is not damaged before treatment. Place fruit to be treated into a cool room at 15°C and hold until 1-MCP application.

Cool room must be air tight to stop 1-MCP gas leakage. Cool room should be capable of holding fruit at 15°C for 24hrs. It is essential to circulate air during the 24hr treatment via cool room forced air or a simple pedestal fan. Then ventilate the cool room for 30mins after 24hrs. It is critical to apply 1-MCP at either 15º or 20°C and not 0°C to avoid internal blackening.

Hydrated lime should be available to reduce excess CO2 build up in the cool room. Place lime in a flat tray approximately 2.5 cm (1 inch) thick.

Temperature: 15°C~20°C

Concentration: 0.5~1μL/L

Duration: 12~24h

5.Storage condition

5.1 Cold room control

Once fruit has been treated with 1-MCP it can be packed and sent to market straight away or cool stored for later packing and marketing. Depending on regions treated fruit is to be stored at 0-1°C for between 4-12 weeks. Treated fruit can be stored for 2-3 weeks at 15°C if desired.

Chilling injury is the main physiological disorder during cold storage. The incidence and severity depend on temperature, cold temperature duration, and the cultivar. For example, ‘Fuyu’ is chilling sensitive while ‘Hachiya’ is not. Chilling injury can be a major cause of deterioration of ‘Fuyu’ persimmons during marketing. Symptom development is greatest at 5°C to 7°C and slowest at 0°C, which is the recommended storage and transport temperature for persimmons. ‘Fuyu’ fruit exhibit symptoms if held between 2°C and 15°C. Upon transfer to higher temperatures, symptom severity (flesh softening, browning, and water-soaked appearance) increases and renders fruit unmarketable. Shrivelling due to moisture loss may become a problem during storage if the RH in the atmosphere is less than 85%.

Temperature: 0°C~1°C(long term storage)

15°C~20°C(short term storage)

Humidity: 85%~95%

CA storage: O2 1%~3%, CO2 5%~8%

5.2 Sterilization

Sterilize cold storage per two weeks. Fungicide will be better when used in alternatively.

5.3 Ventilation

Ventilate every 15 days, ventilation time is about 30min, ventilation when weather is sun and outside temperature is low.

5.4 Out of stock

When storage has finished, treated fruit should be sent through the packing line or if already packed use appropriate cool supply chains to access markets. Fruit should easily hold firmness during supply chain and shelf life for at least 7 days. Colour and Brix should increase during this period. Warm the persimmons before out of the cold room, otherwise there will be condensate water on the persimmons, then persimmons will be rot easily.

6.Contact us

For more detailed information about 1-MCP on persimmon, please feel free to contact us.